...">

Oyuncak ve Araba gibi tüm ürün üretiminde kalıp sıkma çivisi gerekir. enjeksiyon kalıbı makinesinde sıkıştırma birimi kalıpların (bu eşyaların yapımında kullanılan şekillerin) hareket etmesini engelledikleri için önemlidirler. Kararmış kalplerimiz, çalkantı ve yok oluş içinde / Hâlâ kalıplarımız varsa onları doldurabiliriz. Bu nedenle die çenme cıvataları, imalat sanayinde gerekli bileşenler arasında yer alır.

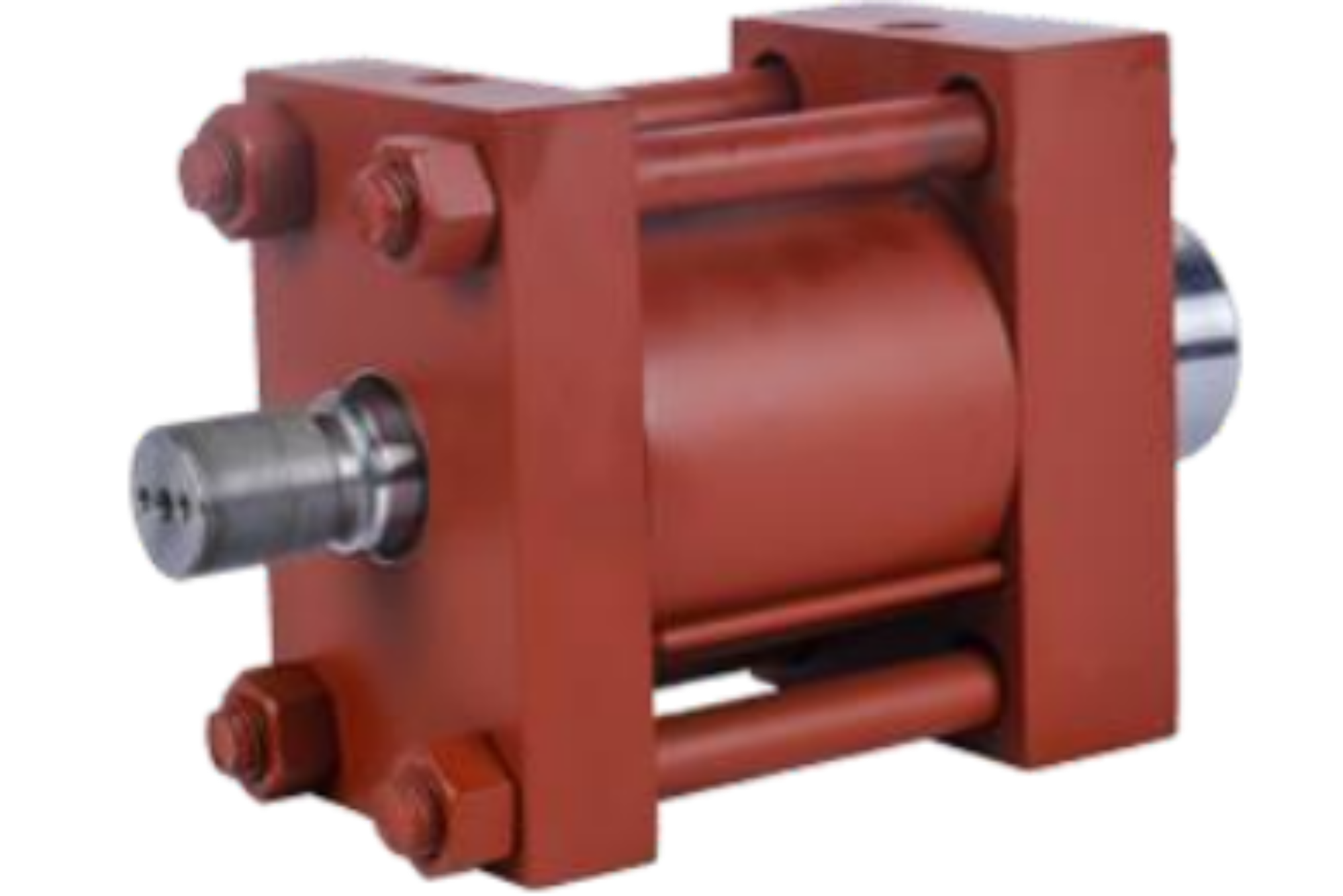

Elle çalıştırılan alkış makası örsü (kaplumbağa ve çekici içerir), Hidrolik örs kavrama bir hidrolik koni içerir. Elle Çalışan Vurucular Elle çalışan vurucular en yaygın olanıdır, burada birey özel bir araç olan anahtarı kullanmak zorundadır. Dolayısıyla, birisi bunları her zaman korumak zorundadır. Bunlar bir makine ile sıkılaştırılırken hidrolik vurucular kilitlemez. Bu da Pingcheng hidrolik vurucuların çok daha hızlı ve basit kullanılmasını sağlar. Her zaman sıkıştırma gücü birimi hızlı kalıp değiştirme için cimri varlıklar için, bu hala önemli olan şirketler orada - ve elle yapılan vurucular daha ucuz olabilir. Tüm bu farklılıklar, vuruç türünde karar veren bir kişi tarafından uzun süre sorulmuştur.

Kalıp sıkma vurucuları doğru şekilde kurulmalı ve bakımlı olmalıdır. Doğru yerleştirilmezse zarar verebilirler. Zamanla bu parçalar düşebilir, zayıflayabilir veya delik açılabilir, böylece insanlar düzenli olarak temizlemezlerse değiştirilmesi gerekebilir. Temiz, sıkı ve doğru şekilde monte edilmelidirler. The hidrolik sabitleme birimi bu sonucunda etkili ve güvenli olmalarına rağmen, düzenli olarak kontrol edilip uygundurlarını görmelisiniz. Pingcheng örs kavrama vurucuları iyi bakımlı tutulmalı, bu da üretimde işlerin akıcı bir şekilde ilerlemesini sağlar.

Kalıp Sıkma cıvatası, kalıpların tüm çıktıların %100 hassasiyet ve doğrulukla sonuçlanmasını sağlama örneğidir. Eğer yuva bile o kadar küçük kayarsa, nesneler yerlerinde duramaz. Kaliteleri düşükse değeri düşer ve kimse almaz. Bu hızlı kalıp değişimi, her şeyin sorunsuz şekilde çalıştığını gösterir. enjeksiyon kalıbı kilitleme birimi her şeyi bir araya getirip kilitleyerek parçaların olması gerektiği gibi oluşturulmasını ve aynı zamanda tüketici kalite gereksinimlerini karşılamasını sağlayın.

Bu belirli mermi için de öyle, doğru kalıp sıkma çivisi seçmek aynı kadar önemli; Her işin birbirine benzemediğini unutmayın, bazı işler gerçekten güçlü montörler ihtiyaç duyar ki bunlar demir gibi ağır malzemelerle uğraşacaklar ve bu çiviler bir şeydir. Ayrıca, bazı iş yerleri hızlı vurucu tornaları gerektirirken, diğerleri yavaş türleri kullanabilir. The shaft kampa birimleri şekli tamamen ne yaptığınıza ve nasıl yaptığınıza bağlı olarak değişir.

Müşteri hizmetlerimiz, kalıp kapatma cıvataları konusundadır. On yıldan fazla bir süredir tornalama hizmetleri sunmakta ve tanınmış Japon şirketleriyle yakın iş birlikleri geliştirmiş bulunmaktayız. Pingcheng’in dürüst fiyatlandırma politikası, bu alanda edinilen on yılların deneyimine ve derin uzmanlık bilgisine dayanmaktadır. Bir fiyat teklifi talebi aldığımızda, çizimleri ve simülasyonları özel yazılımımızda mümkün olan en kısa sürede inceler ve uygun fiyatlı en doğru çözümü sağlar.

Pingcheng günümüzde 20'den fazla üretim tesisi ve die sıkma cıvatalarına sahiptir. Yüksek kalite sunmayı hedeflerler. Mitsutoyo ölçüm cihazları ve koordinat ölçüm makineleri (CMM) düzenli olarak kalibre edilir. Çift kontrol, ürünlerimizin doğruluğunu ve kararlılığını korumamıza yardımcı olur. Her bir bileşen, işlenme ve montaj süreçleri boyunca izlenebilir ve izlenir.

Pingcheng'in kalıp sıkma cıvataları, sektördeki on yılların tecrübesi ve derin bir anlayış üzerine kurulmuştur. Teklif taleplerini aldığımızda çizimleri inceler ve özel yazılımla simülasyonu hemen yaparak adil bir fiyatla en etkili çözümü sunarız.

Pingcheng'ın die sıkma cıvataları ve hizmetleri, müşterilerin iş amaçlarına ulaşmalarına yardımcı olacak şekilde tasarlanmıştır. Üretimlerinizin potansiyelini ve ömrünü genişletmeye ve artırmaya odaklanıyoruz. PingCheng, aradığınız güvenilir üreticidir. Fırsatlar sunan bir tedarikçiyiz.