Mesin Casting Die Dijelajahi

Selamat datang di Dunia Casting Die. Bagian logam dibuat dengan bantuan mesin-mesin cemerlang ini, yang menggunakan proses casting khusus yang sangat penting dalam manufaktur. Sekarang kita akan membahas beberapa aspek yang menjelaskan sifatnya serta utilitas optimal dalam berbagai industri untuk mesin casting die.

Berurusan dengan Mesin Casting Die

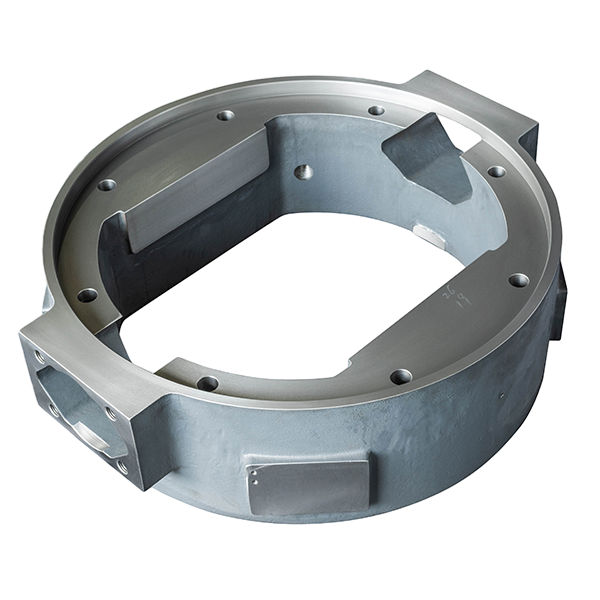

Mesin die casting telah menjadi salah satu alat intelektual untuk mengecor logam cair menggunakan rongga cetakan untuk membuat produk dengan presisi. Kemudian mesin tersebut menyatukan berbagai bagian secara harmonis untuk menghasilkan hasil berkualitas tinggi. Mesin ini dapat memproduksi sejumlah besar bagian dengan kecepatan tinggi dan presisi ekstrem, dibandingkan dengan teknologi pengecoran tradisional seperti pengecoran pasir atau pengecoran gravitasi.

keuntungan dan inovasi

Mesin die casting merupakan salah satu keunggulan utamanya, karena peralatan ini dapat memberikan dimensi yang lebih presisi dan permukaan yang lebih halus serta sifat mekanis yang kuat. Dengan berjalannya waktu, peralatan ini telah banyak berkembang untuk mencapai akurasi dan efisiensi yang lebih baik. Mesin die casting modern menggabungkan inovasi dalam kontrol, robotika, dan sistem pemantauan proses dengan kemampuan kuat untuk menghasilkan bagian-bagian berkualitas secara konsisten.

memprioritaskan keselamatan

Ketika mengoperasikan mesin injeksi logam cair, keselamatan adalah poin yang paling krusial. Mesin-mesin ini dilengkapi dengan tindakan keselamatan lainnya seperti pelindung, sakelar keselamatan, dan tombol darurat untuk menjaga operator dari bahaya. Selain itu, dalam kepentingan terbaik kami untuk membekali dan melatih operator mesin ini agar mereka dapat melakukan pekerjaan mereka dengan aman tanpa kecelakaan.

aplikasi yang beragam

Rentang penggunaan akhir sama bervariannya dengan bahan tersebut, tetapi pengecoran logam cair paling sering digunakan dalam elektronik konsumen dan manufaktur industri. Selain itu, mereka juga berkontribusi pada produksi komponen utama seperti blok mesin, casing transmisi, dan bagian elektronik. Untuk itu, mereka dirancang sesuai dan dapat menangani berbagai jenis logam seperti aluminium, seng, dan magnesium; sehingga membuktikan fleksibilitas mereka juga.

Pedoman Operasional

Mesin injeksi logam tidak berbeda. Operator harus mengetahui cara mengatur mesin dengan benar, memuat logam, dan memulai proses pengecoran. Bagian lain yang penting adalah pemantauan konstan, penyesuaian, dan mendeteksi kesalahan saat bekerja dengan mesin. Penting bahwa operator telah dilatih dan bersertifikat untuk mengoperasikan mesin secara efisien.

Menjamin Efisiensi Mesin

Rentan terhadap kerusakan seperti setiap mesin lainnya, menjaga standar perawatan tinggi sangat penting agar mesin injeksi logam dapat terus bekerja secara efisien. Mereka juga menyediakan layanan perawatan dan perbaikan untuk menjaga fungsi efisien dari semua mesin ini. Pemeriksaan rutin, pembersihan, dan pelumasan akan mencegah mesin cepat rusak.

Standar Kualitas

Dalam proses pengecoran logam cair, pengendalian kualitas sangat penting. Untuk membuat bagian yang presisi dan konsisten, mesin harus memenuhi beberapa kriteria seperti mengontrol suhu dan tekanan secara akurat selama proses pengecoran. Kualitas optimal juga memerlukan laju pemberian yang konsisten dan penghapusan kekotoran dari logam.

Aplikasi Serbaguna

Jadi, mesin pengecoran logam cair sangat cocok untuk memproduksi komponen yang membutuhkan kekuatan tinggi, stabil secara dimensi, atau memiliki bentuk yang kompleks. Pelanggan mereka berasal dari berbagai industri, termasuk otomotif, penerbangan, atau sektor medis. Selain itu, mesin seperti ini mendorong produksi produk akhir seperti mainan, barang olahraga, dan aksesori elektronik.

Sebagai kesimpulan

Untuk menyimpulkan, mesin injeksi logam cair adalah salah satu peralatan paling penting dalam kehidupan kita. Mereka memiliki kecepatan tinggi dan pewarnaan yang sangat akurat, cocok untuk pembuatan bagian yang kompleks, membuatnya lebih unggul dibandingkan metode pengecoran lainnya. Hari ini, dengan penemuan baru dan perhatian yang teliti terhadap kualitas, mesin injeksi logam cair ini terus memainkan peran mendasar dalam penciptaan komponen kelas atas yang digunakan oleh berbagai jenis industri.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI