An Introduction to Injection Molding Machines, Including Their Three Major Components

Plastic items are produced by the usage of an injection molding machines. It includes three main units which are collectively produce these products. Now let us get a bit more detail into each of these unit so that we can understand what they are doing and why do we need them in the production process.

Unit 1: Injection Unit

The injection unit is often the very heart within the moulding machine. This unit is doing processing of raw plastic material to a pliable formIt helps the shaping easy Hopper Heater Screw Barrel Essential Components Above this are the hopper, in which material is preserved, and the heater to melt it down,A screw that clears molten plastic upThe barrel where until-is built into shape.

Advantages:

It uses an injection unit whose design contributes to the high-quality endproduct and it does so with accurate.mixing.

It used less power and material than the other plastic manufacturing methods thus reducing its costs.

Innovation:

In addition, the sensors of modern injection units are able to determine deviations in material composition and independently correct temperature or pressure parameters.

Safety:

Injection molding machines are generally safe, yet operators should be aware that the injection unit is hot and avoid contact while the machine is in production mode.

Use:

The injection units are designed to be versatile platforms capable of manufacturing products within a wide range and complexity.

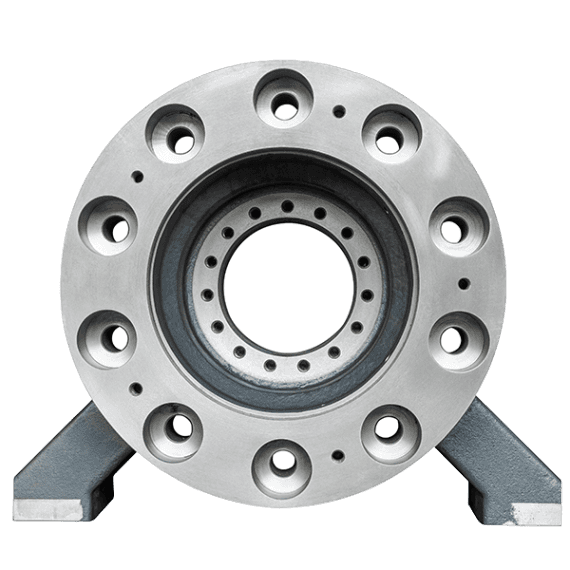

Unit 2: Clamping Unit

The clamping unit is essential to engage and lock the mold during injection. It includes a pair of frames that are affected by hydraulic or mechanical methods to reserve the mold at its place.

Advantages:

The purpose of the clamping unit is to prevent instability and ensure accuracy during the molding operation.

It helps to maintain the mold integrity when production process takes place.

Innovation:

Modern clamping units also incorporate the sensors that read pressure readings to prevent mold damages from occurring on account of deviations in thermostat.

Safety:

Clamping anti-theft mechanical unit must be forged when clamped to avoid accidents, and safety protection should be worn.

Use:

This allows the clamping unit to accommodate a wide range of mold sizes and geometries while producing an assortment of parts.

Unit 3: Ejector Unit

The ejector unit removes the part from the mold after it is manufactured. The die set includes the stripper plate, pins, and hydraulic or mechanical actuating devices.

Advantages:

The ejector unit is used for mass production of items and helps to quickly remove the finished article in order to produce even more.

This unit facilitates the uninterrupted production of ready products by attending to and cleaning the mold for another cycle.

Innovation:

Modern ejector units have Sensores that will drive the machine to turn off Visio of each house mold been ejected.

Safety:

When used properly, the ejector can be operated safely to ensure rapid and safe workplace.

Use:

The ejector unit is what propels the final product from its mold to resume rapid production of new parts.

Conclusion:

So, in order to make good use of injection molding machines you should be familiar with how the three main units work and their importance. With a focus on protective measures and operational instructions, people can utilize injection molding machines that are best suited to manufacture high-grade plastics in long production very effectively. Remember, safety first!