Injection molding machines are with possibility status in Japan about the plastic part production. Japanese machines are known for their excellent build quality and cutting-edge features. Here, we are going to know about the top five leading machines in Japan and why they take injection molding machine needs a level up. The of the well used machine in all industries due to user-friendly and easy maintenance.

The Japanese moulding machine are known for their precise and accurate production of even the most intricate of products. They are computer-controlled, so each injection is consistent and accurate enabling high production rates at a low cost per part.

Japanese machine makers have a proud tradition of always making their machines better each time. The company has produced machines that mold parts with multiple materials at the same time and change molding parameters to increase control over how a final part is formed. There are also continued advancements in hybrid machines that incorporate electric and hydraulic technology to offer greater efficiency as well.

The safety of Japanese injection molding machines is top-notch. Including, but not limited to protective doors and sensors which are designed to detect that an accident may be about to happen so it can stop the machine before putting harm at the first place.

The benefit of the Japanese injection molding machines is in having a versatile range that can be used for many industries whether it may be automotive, construction or medical devices as mentioned by Arif. Those machines are great in making different PP parts including covers, knobs and WF containers & bottles, so these well reflect their versatility.

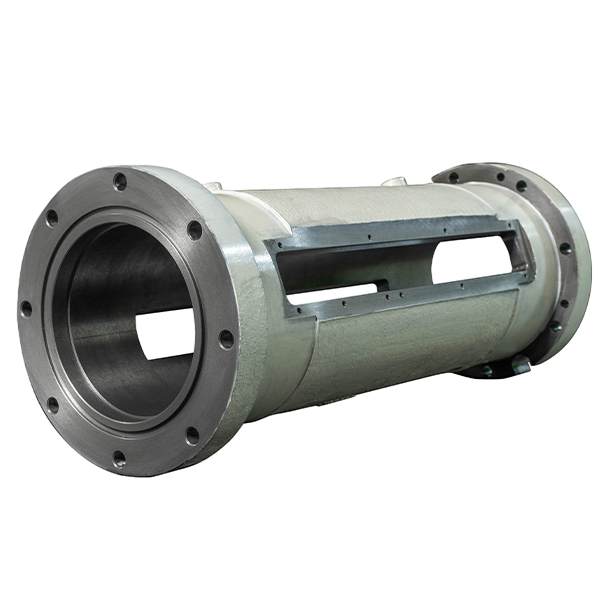

To begin, a quantity of small plastic pellets are placed in the hopper atop the barrel of our reciprocating screw injection molding machine. The plastic is gradually channeled down through a heated nozzle and into the melting compartment serving to liquefy it due to friction generated by kneading screws contained therein. Further post moulding processing, clear the way for final part completion.

Japanese manufacturers also provide complete maintenance and repair services for their injection molding machines to keep them running smoothly. These machines are built with the best materials and tested to perform perfectly under most circumstances, they also come with a warranty which gives all costumers peace of mind. Operational reliability and unprecedented levels of economy are some of the unique aspects provided by Japanese injection molding machines Place their clients in a position to doall they require throughout several diverse sectors advanced solutions, as long as investors have chosen superior-grade systems.