ومع ذلك، في بينغتشنغ نعتقد أنه من الضروري جدًا اختيار النهج المناسب لإحياء منتجك. على الرغم من وجود العديد من الطرق لتصنيع الأجزاء لصناعات مختلفة، فإن تشكيل الحقن وصب القوالب بينغتشنغ هما من أكثر الطرق شيوعًا. فهم الطرق المختلفة التي تُستخدم بها هذه الأساليب لتصنيع مجموعة متنوعة من المنتجات سيساعدك بشكل أكبر في اتخاذ القرار الصحيح وفقًا لاحتياجاتك.

ما هو صناعة القالب بالحقن؟

التشكيل بالحقن هو عملية حقن البلاستيك الساخن، المذاب داخل تجويف (قالب) يمكن أن يكون له أشكال مختلفة. هذه التقنية رائعة للبلاستيك الصغير إلى المتوسط مثل الألعاب، العجلات، والأجزاء الإلكترونية. التشكيل بالحقن هو أحد العمليات التي تنتج أشكالًا معقدة جدًا. مما يعني منتجًا أنعم تمامًا كما تريد التصميم. فائدة أخرى كبيرة هي حقن القالب سرعة التشكيل بالحقن حيث يمكنه إنشاء العديد من المنتجات المتطابقة في وقت قصير، مما يسمح بإنتاج عالٍ في وقت قصير جدًا.

ما هو صب القوالب؟

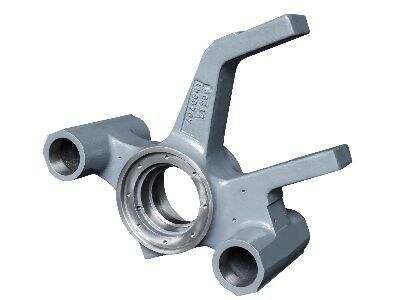

من ناحية أخرى، صب الدي يُعد عملية صب معدن ساخن ومذاب في قوالب فولاذية. هذه هي العملية التي يتم فيها وضع المعدن المنصهر في القالب لتشكيل المنتج النهائي. يعتبر صب الدي رائعًا لإنشاء مكونات معدنية دقيقة. يمكن استخدام هذه التقنية لمجموعة واسعة من المنتجات، بما في ذلك مكونات السيارات، وأدوات المطبخ وأنواع مختلفة من العناصر المعدنية. تُستخدم القوالب في صب الدي وهي معدنية، مما يسمح بإعادة استخدامها عبر دورة متعددة. كما أنها تسهل العملية بأكملها وتوفّر المال في النهاية.

المزايا والعيوب لكل عملية

الآن، سنغوص بشكل أعمق في المزايا والعيوب المرجوة لهذه العمليات بين تشكيل بالحقن وصب الدي.

تشكيل بالحقن:

المزايا: إنها قادرة على إنتاج هندسات معقدة للغاية وهي مثالية لطباعة ثلاثية الأبعاد لمكونات بلاستيكية عالية الجودة. كما أنها ذات كفاءة عالية، حيث تستطيع تنفيذ العديد من المهام الإنتاجية بسرعة واتساق لا يمكن للمانين مطابقتهما.

العيوب: من ناحية أخرى، تكون الآلات المستخدمة في تشكيل الحقن مكلفة جدًا. بالإضافة إلى ذلك، صنع القوالب المطلوبة لهذا العملية قد يستغرق وقتًا طويلاً، مما قد لا يكون مناسبًا لجميع المشاريع.

الصب بالنقالة:

ملخص: ومع ذلك، فإن صب القوالب هو خيار رخيص للمكونات المعدنية. هذا آلة تشكيل بالحقن العمودية يتيح الدقة العالية، والتي تكون ضرورية للكثير من السلع.

العيوب: أول عيب في صب القوالب هو أن ليس كل المواد يمكن استخدامها. بالإضافة إلى ذلك، يمكن ترك القطع المصنعة بعيوب طفيفة على السطح قد تؤثر على الجمالية للمنتج النهائي.

المعدات المطلوبة

ثالثًا، لأغراض تشكيل الحقن، لديك أيضًا بعض المعدات المهمة لاستخدامها. تحتوي على ماكينة حقن البلاستيك، قالب ووحدة حقن. تقوم آلة حقن البلاستيك 0achie بتسخين المادة البلاستيكية وخلطها ثم حقنها في التشكيل. يكون القالب باردًا ويبرد البلاستيك لتشكيل المنتج النهائي الذي تريده.

يُطلب معدات إضافية لعملية صب القوالب. وتشمل هذه المعدات جهاز حقن المعادن، والقالب والموULD. في جهاز حقن المعادن، يتم تسخين المعدن حتى نقطة الانصهار ويتم حقنه داخل القالب تحت ضغط عالٍ. بينما يتحكم القالب في تدفق المعدن إلى القالب، فإن القالب يشكل المعدن إلى الشكل المطلوب.

التكلفة والكفاءة

يمكن أن يكون هناك فرق كبير بين معدات الصب بالحقن وصب القوالب. تكون آلات الصب بالحقن غالية الثمن للغاية، حيث تتراوح تكلفتها من بضعة آلاف من الدولارات إلى مئات الآلاف من الدولارات اعتمادًا على الحجم والتعقيد الجزء. وعلى الرغم من كونها مكلفة، فإن عمليات الصب بالحقن فعالة للغاية ويمكنها تصنيع العديد من المنتجات في وقت قصير.

من ناحية أخرى، تكون آلات صب القوالب أرخص من آلات الصب بالحقن، مما القولبة بالحقن العمودي يمكن أن يكون مفيدًا للكثير من الشركات. وعلى الرغم من كونها أرخص، قد تكون عملية صب القوالب أبطأ وأقل كفاءة من نواحٍ أخرى، لذا يجب مراعاة العوامل عند اختيار العملية.

ملخص

لخصّة، كل من تشكيل بالحقن والصب بالنماذج لديهما نقاط قوتهما وضعفهما الخاصة. يتم تحديد العمليات التصنيعية المثالية بناءً على متطلبات المنتج. عند إنتاج المكونات المعقدة من خلال أجزاء بلاستيكية، يوفر تشكيل الحقن حلولًا منخفضة التكلفة ودقيقة للغاية، بينما يعتبر الصب بالنماذج الأفضل لإنتاج أجزاء معدنية دقيقة وبكميات كبيرة. في شركة بينغتشنغ، نرشد العملاء ونعمل معهم لاختيار العملية التصنيعية المناسبة التي توفر منتجًا عالي الجودة وبسعر معقول. هذا يمكّنك من اتخاذ أفضل القرارات الممكنة حول مشاريعك.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI