These Flanges are used for connection of pipe, valves and other equipment to pipes in different industries. These are highly versatile elements which come in a variety of shapes, sizes and materials each serving different purposes.

Flanges have various materials such as stainless steel, carbon steel, and brass that are made according to the characteristic of each material. For example, most users of stainless steel flanges use them in the harshest environment as they are rugged and do not corrode easily. Brass flanges, on the other hand are ideal for applications with water activities.

In addition flanges have a variety of shapes and are custom designed to meet the needs. Some types of flanges are easy to install and remove, others offer great strength or durability (weld-neck etc...) Lap Joint Flanges : Lap-joint flanges are used in piping systems that require frequent dismantling for inspection, cleaning and replacement. - Socket Welded Threaded Flange Find size of small-bore (1/2"), as they can be welded into place.

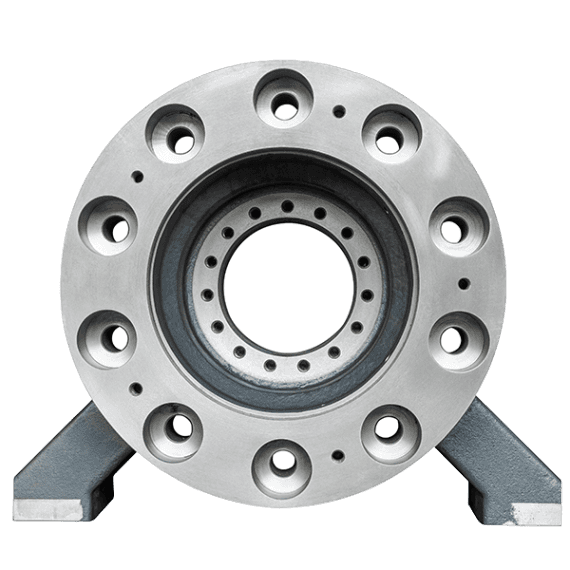

Flanges constitute a huge family; each type of flange has its unique characteristics. SOME OFTEN-USED FLANGES ARE:

Weld Neck Flanges: Well neck flange with long welded doffer, it great efficiency and safety.

Slip-On Flanges - They are designed for easy of fitting in and removal.

Socket Weld Flanges = This is similar to a slip on flange in outline, but the bore is counter-bored to accept pipe.

Threaded Flanges: They are screwed onto the pipe and they provide a little better durability.

Blind Flanges - these work to seal pipe or valve ends

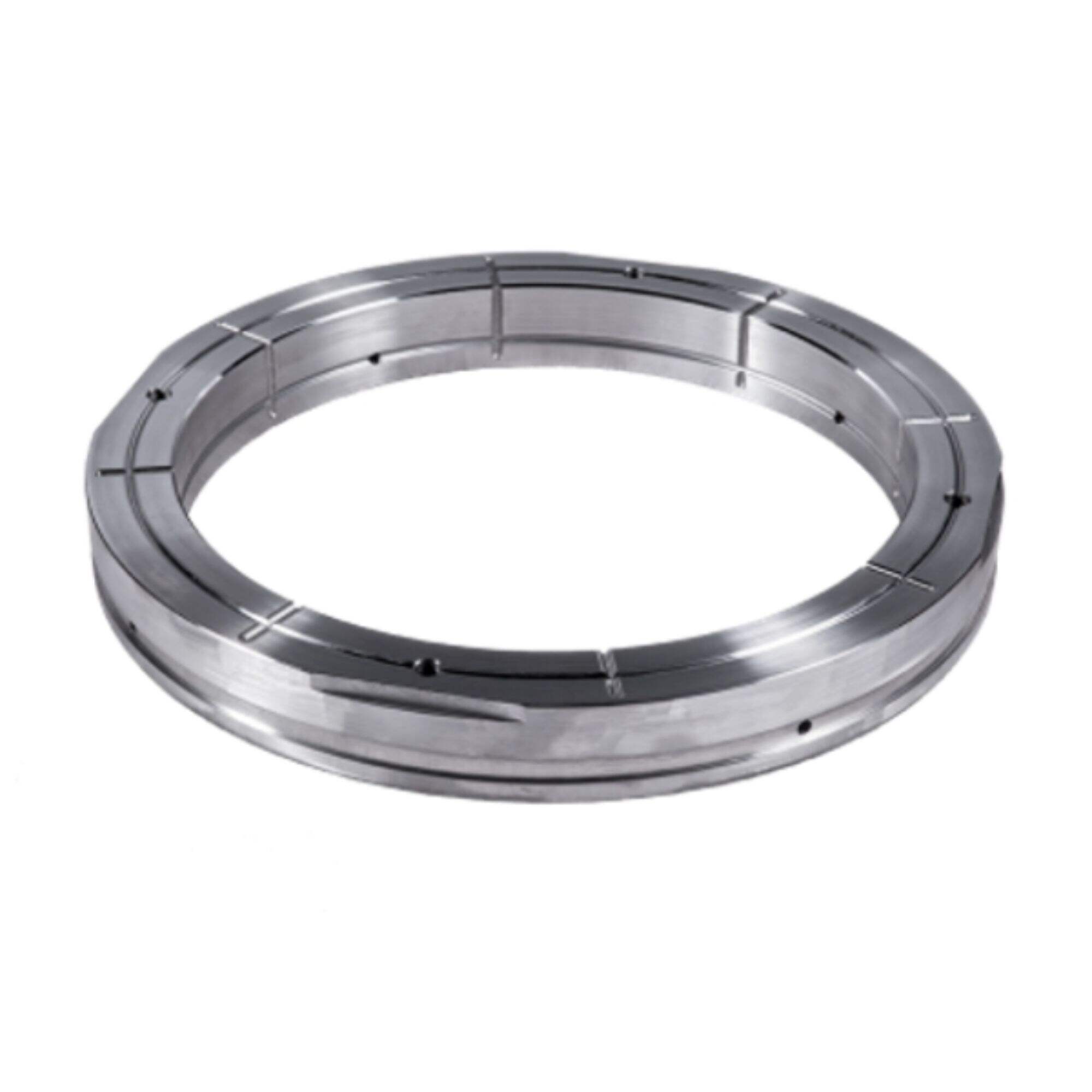

Flanges are having different face types such as flat face, raised face and ring joint form (RTJ) used for Sealing of flange connections with gasket materials. Moreover, flanges are available in various standards such as ANSI/ASME B16. 5, B16. 47, and API 6A specifying their dimensions an pressure ratings that are essential for a secure non-leak connection.

Different sectors require different types of flanges in order to meet their needs. For instance, ring joint flanges are frequently used in the oil and gas sector while slip-on flanges are favored in food & beverage applications. Pharmaceutical environments usually have stainless steel flanges, while plumbing applications use brass flanges.

There are categories over and above the typical sorts that include things like spectacle blinds as well expander flanges. Used to temporarily stop the flow, spectacle blinds are comprised of a central hub and two metal discs. On the other hand, expander flanges effort short transfer enlargement in pipe systems by means of a straight hub exactly similar to be good as an imbecile lap joint on your go at with furthermore will burst rapidly into little bit larger than life- span flat.

Flanges have similarly great importance in industrial applications. However, by exploring the wide range of flange types and choosing the best one suited to your project, you can maintain a secure and leak-free joint according to its requirements.

Pingcheng has at different types of flange and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Pingcheng is dedicated to helping customers different types of flange by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Our customers service focuses your satisfaction. We've been providing machining services and different types of flange with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate different types of flange as soon as we can, and provide the best solution for your cost.